News

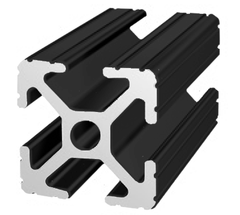

Safety guarding, barriers and enclosures have a lot of utility in a manufacturing environment, and more and more companies seem to be migrating to aluminum extrusions for this purpose. Our company builds industrial framing using 80/20 brand aluminum t-slot extrusions including safety guarding, temporary walls, barriers and machine enclosures.

T-Slot Extrusions Offer Multiple Advantages

Aluminum t-slot extrusion structures can provide increased efficiency, better manufacturing yields, higher employee morale, and provide more employee safety if properly designed. The primary functions of a guard, a barrier or an enclosure are as follows:

- Prevention of entry into a dangerous area

- Prevention of injury in areas of moving mechanical parts

- Prevention of injury due to flying objects

- Prevention of injury due to explosion/fire

- Reduction or elimination of debris spread from process

- Reduction or elimination of airborne particles from process

- Sound dampening and hearing protection

- Containment/separation of components within a process

- Provide awareness of danger

- Provide security and protection for valuable or fragile items.

- Adheres to standards such as OSHA

T-Slot Extrusions Are Easy To Configure

In its most elementary form, aluminum t-slot extrusions are connected together using extremely strong fasteners to create a basic frame. This allows them to be built on-site. The advantage of this is that you build a large structure in a room with a small doorway. It’s also a clean process; whereas, building on-site with wood or welding steel will create large contamination areas and may require ventilation and other environmental controls. And unlike wood or steel, structures made from t-slot extrusions can be easily disassembled and reassembled. For example, if you want to enlarge or make a structure smaller, you can do this easily.

T-Slot Extrusions Are Easy To Customize

Many industrial guarding projects or enclosures include walls, fences, doors, window, and other functional features. These are easy to design and implement using a wide variety of panel materials. These “panels” can provide entry/exit functionality, provide safe viewing, contaminant containment, projectile containment, sound abatement, and product movement through an automation system. Panel segment are usually referred to as walls, doors, floors and ceilings when designed for guarding or enclosures. And they can be sized and located to fit specific requirements for each application or company.

Choosing The Right Panel For Your Framing

Panels work together with the aluminum t-slot framing to complete the safety guard, wall or enclosure. Panels are often made of clear polycarbonate when observation of the internal process is warranted, with polycarbonate being the safest clear material for non-blast applications. Clear acrylic can be used in some applications, but it can shatter when subject to an impact or an explosion. Glass is prohibitively expensive and can also shatter, unless blast-resistant glass is used which is on the most expensive side of guarding materials.

Wire mesh, aluminum plates, and plastics such as HDPE and ABS are also popular panel materials. Wire mesh, for example, allows observation and security while presenting less of a complete barrier than solid panels. In many cases where flying debris and airborne particulates are not a safety concern, wire mesh can be a better alternative than solid panels. Wire mesh and expanded metal are common panel types for security cages and structures.

For panels where visibility is not required, common materials such as ABS and HDPE provide low-cost containment and safety. They are easily machined and come in a wide variety of color options.

Functionality For Guarding

Doors small and large are often added to an enclosure or safety guard to provide functional access when it safe. Doors can be fitted with electronic sensors that turn off a machine or a process when a door is opened to ensure operator and outside personnel safety. Doors and hatches allow faster and easier maintenance of a machine or process when the guarding is placed in close proximity to the machine or process. In situations where complete temporary clean rooms are built around a process, doors may provide access and awareness that they are entering a different environment.

Ceilings on larger enclosures provide more complete containment, and a structure to mount lighting and filters such as commercial HEPA filters to. Ceiling design requires careful assessment of the fire code, as they can hinder internal fire suppression systems – so choosing the design of the overall safety structure has multiple requirements.

Mounting To T-Slot Extrusions Is Simple

Besides being almost as easy to assemble as “Legos”, aluminum t-slot extrusions offer superb utility when it comes to customization and mounting other items such as computers, control boxes, arms, shelves, racks, tables surfaces, valves, boxes, etc. The “t-slot” of the bar when used with a “t-nut” provides this utility by allowing basic bolts to connect to the sliding, threaded t-nut in the slot (as long as it has the right thread size). The ability to mount anything easily anywhere on the structure makes aluminum t-slot extrusions a very flexible system for changes or adjustments over time.

T-Slot Extrusions Are Light, But Strong

Unlike welded steel structures, aluminum is light yet strong. For the same strength, its about ½ the weight of steel – making structures easier to move and easier to assemble. And as they can be carried into a space as individual components (before assembly), the possible methods of transportation are much more flexible. For example, you can ship small structures in boxes by UPS or Fedex, and hand carry them into a building versus using a forklift and a crane for a welded structure.

Aluminum Is Preferred For Clean Environments

Aluminum offers superb corrosion resistance, and over time, puts less airborne particles in the air; hence, its preferred status within the clean room community. While Aluminum can corrode, most t-slot aluminum extrusions are anodized, providing a hard coating that prevents airborne and waterborne corrosion.

Cost-Effective Solution

Custom guarding, barriers and enclosures made from aluminum t-slot structures offer easy and inexpensive customization and so many other benefits to manufacturing engineers, facility managers and safety officers. And because it can be disassembled and repurposed later in life, it offers unparalleled value for your investment dollar. So when you are next faced with a manufacturing challenge or safety concern, remember that aluminum t-slot extrusions can be an excellent cost-effective solution.

At F&L Industrial Solutions, we design, machine and build guards, barriers and enclosures almost every day and we offer free design services to create the framing solution that is just right for you. We are a Tier 1 authorized distributor and manufacturer for 80/20 brand aluminum t-slot extrusions. All we need to get started is a sketch with dimensions with call-outs for any doors or hatches you want or need. We would be happy to send you a quotation at no charge, just email us at: info@fandl8020.com or call us at 1-858-602-1500. We will be happy to help you.

Collections

- 10 Series Bars - 1"

- 10 Series Parts

- 15 Series Bars -1.5"

- 15 Series Parts

- 20 Series Bars - 20mm

- 20 Series Parts

- 25 Series Bars - 25mm

- 25 Series Parts

- 30 Series Bars - 30mm

- 30 Series Parts

- 40 Series Bars - 40mm

- 40 Series Parts

- 45 Series Bars - 45mm

- 45 Series Parts

- Bestsellers

- Quick Frame - 1" Sq. Tubing

- Ready Tube - 1.5" No T-Slots